GEM has been a leader in the mobile water treatment industry for over two decades. Our teams of water treatment engineers are available to perform local and remote treatment projects at a moment’s notice. We take a consultative approach to developing treatment methodologies, where we interview our customers to determine project goals prior to mobilizing equipment. The foundation of our water treatment program has been built around project flexibility. When projects are complex, GEM often offers multiple treatment technologies in sequence in order to meet project treatment goals, recycling criteria or discharge standards.

Process Water

The Clean Water Act defines Process Water as any water that, during manufacturing or processing, comes into direct contact with or results from the production or use of any raw material, intermediate product, finished product, byproduct, or waste product. Examples would include water used for washing, rinsing, direct contact, cooling, solution make-up, chemical reactions, and gas scrubbing in industrial and food processing applications. GEM has a wealth of experience treating such process water from a cross-section of industries and can respond immediately to tackle any project.

Remediation & Groundwater

Groundwater remediation is the process of removing contaminates from groundwater. While most groundwater is clean, industrial practices of our not-so-distant past have negatively impacted our nation’s water table and treatment systems are necessary for clean-up. GEM has performed ground and surface water treatment for over two decades and continues to manage simple and complex projects today. Sources of contamination can range from over application of fertilizers, leachate from landfills to spills from industry. Regardless of the contaminants, GEM has a solution.

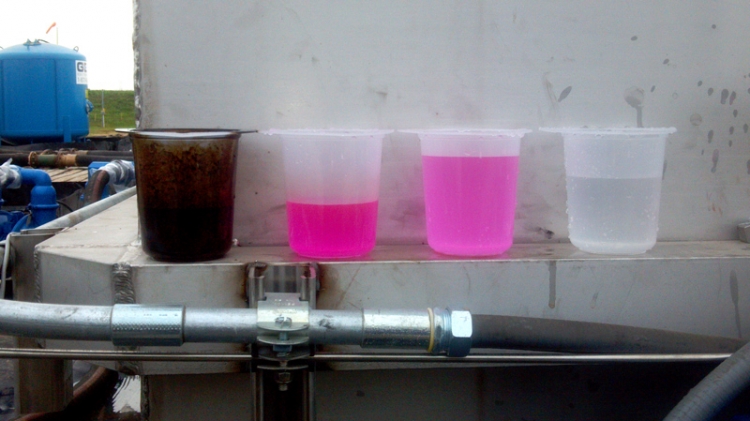

Hydrotest Water

GEM is an industry leader in on-site treatment or filtration of hydrostatic pipeline test water. Our teams have performed treatment projects from dense cities to remote locations. We have experience in handling project flows up to 15,000 gpm. Projects where pipelines are being cleaned, hydrotested, or pigged will generate large quantities of contaminated water. GEM’s treatment systems are available to mobilize on quick notice for project set-up and treatment. Our treatment systems meet the most stringent NPDES or POTW discharge standards.

Turnaround Water

Facility outages or turnarounds generate large quantities of rinse, decontamination, or process waters. Water management can pose a challenge as turnaround managers struggle with on-site treatment, cost control and project efficiencies. Typically, the costly rental of numerous storage or frac tanks provides temporary storage of contaminated water when it can’t be managed as quickly as it’s generated. Additionally, a plant water treatment facility is not accustomed to the water and contaminates generated from the cleaning process. GEM has proven experience in treating vessel or unit rinse or process waters to discharge standards while the turnaround project is on-going, eliminating the need for additional storage tanks and avoiding the facility treatment works.